Autonomous Positioning System

The intelligent solution to avoid taglines

Avoiding taglines will improve

The APS solution is our latest innovation, delivering improvements in safety, permitting and efficiency. The technology is specifically designed to align wind turbine components without the need for taglines.

Handling and controlling lifting operations

Lift your safety to a higher level

Our APS system is developed to increase the safety of lifting operations by providing reliable and accurate remote control of your load. The system is designed with redundancy on all systems, eliminating the need for tagline systems. This eliminates the need for personnel on the ground next to or directly under your lift.

Manually operating taglines poses several risks of injury. Burns, dislocated shoulders and back injuries are common. There are additional risks when working outside the excavated areas of a wind farm, such as twisted ankles and snake bites. All of these safety risks scale with the size of the turbine.

-

“The APS System has made our lifting safer for our personal”

– Guido Hinrichs, Vice president of construction at VESTAS Latin America -

“This tool is a game changer”

Michael Thomas, Nordex -

“The APS has reduced our installation time

and made our installation more precise and safe”Jens Koalick, construction manager at VESTAS Central Europe

Protecting nature is key to approval of new wind park installations

The Autonomous Positioning System reduces the need for excavation by eliminating the need for remote tagline operators or winches.

As a result, the turbine hardstand is often limited in size and must be used very efficiently with just-in-time arrival of components on the pad. The APS supports the rapid hoisting of components without the slow and risky handling of taglines from outside the pad area.

Renewable energy is in high demand, yet fragile natural areas must be preserved.

100

Units sold worldwide

Increase your wind speed limit

The Autonomous Positioning System promotes precise and innovative positioning. This helps expand your operating and weather window – and reduces your installation time. Successful wind turbine blade installation in wind speeds up to 14 m/s.

As wind turbines become larger and taller, the cost of installation cranes increases.

Cranes used to install larger wind turbines now need to work in all weather conditions. Snow, fog, strong winds and gusts are more likely to occur in the fall and winter.

The Autonomous Positioning System ensures that the main crane continues to operate regardless of low visibility, snow and other seasonal weather conditions.

Efficiency

The APS increases the operating weather window to overcome high winds and low visibility. This increases the utilization of the main crane and improves the predictability of the installation schedule.

Integrable system

The Autonomous Positioning System can be easily attached to or integrated with existing lifting equipment. Whether you need to lift wind turbine components or assemble bridge sections, the only limit is your imagination.

Fast and reliable assembly

The APS system can be permanently integrated into your lifting device. Or it can be shipped with our quick snap system – if you need to use the APS system on more than one hoist at the same jobsite or lifting operation.

Increased safety

Avoid taglines / no people in installation zone

Less direct cost of wind

14 m/s (less waiting and WTG downtime)

Reduced risk profile

Install during windy/inclement weather

Reduce project duration

Get early generation bonus

Leverage of the portfolio

Installation during the winter season

Reduced wind days for main installation

Installation of more WTGs during summer

FOI deal maker

Due to early production start

More precise CMII forecast

Due to reduced cost volatility

Renewable Energy, s.a. announces: „Significant event“:

“Quarterly performance (Q1 2020) has been impacted by […] €150m in a portfolio of five Onshore projects […] driven by […] an early arrival of winter weather that have delayed project execution substantially.”

Nordex Annual Report

“Deviations from predefined process chain may be caused by weather risk, which may lead to […] cost overruns for cranes and assembly work”

Autonomous Positioning System

The APS is an original and very popular positioning system, due to its reliability, functionality, and practical design that ensures easy handling, alignment and control.

-

Higher safety and reduced risk profile

-

Less direct cost of wind

-

More precise CMII forecast

-

Reduced project duration

Technology & Specifications

-

Technology

Solving major planning challengesThe APS solves a major challenge when our customers install components on wind turbines. Especially near highways, in forests, in mountainous areas and other places where traditional solutions like tagline systems can’t be used. The system is not limited by distance or the size of hardstands.

Why is this important?

Installing renewable energy sources, including wind farms, close to where the energy is consumed reduces the need to transport energy and the resulting losses. Respecting neighbors and planning around existing infrastructure is important when installing wind farms in populated and congested areas, however, and is a delicate exercise.

Smoother planning by avoiding taglines

Avoiding taglines is an effective way to avoid conflicts with neighbors who are reluctant to allow access for tagline operators or even reels. Avoiding taglines also reduces the need for local authorities to allow temporary closures of busy infrastructure such as highways. This ensures smoother planning and execution of wind farm installations.

-

Technology explained

Development in need of tagline operatorsStronger winds, and the resulting lower tagline force at ever higher hub heights, is an escalating problem in the installation of wind turbine components.

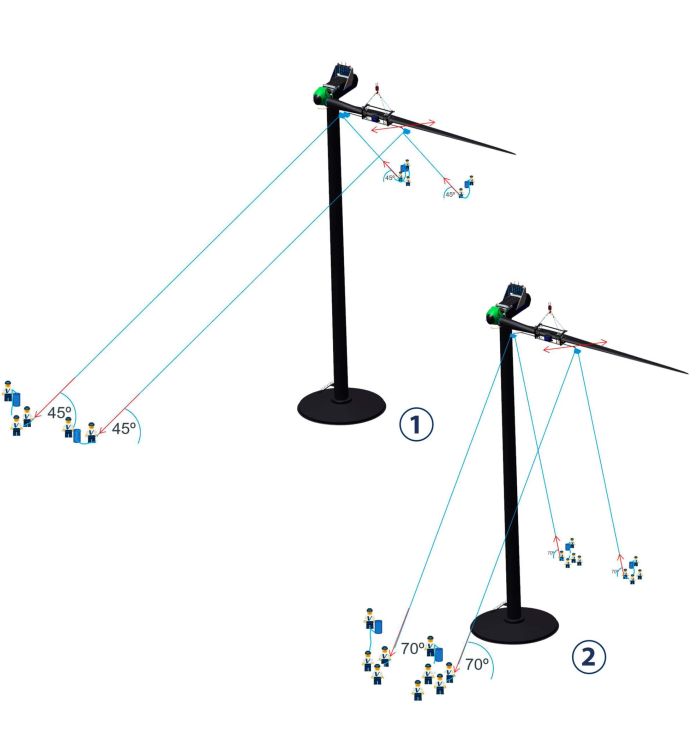

Facts:

A person who can pull 75 kg will apply 53 kg of resultant force at a 45° tagline angle, and only 25 kg at a 70° angle.1 explained:

- Horizontal force: 45° (53 kg per person)

- Windspeed: 9 m/s

- 10 technicians total for taglines

2 explained:

- Horizontal force: 70° (25,7 kg per person)

- Windspeed: 11 m/s

- 19 technicians total for taglines

-

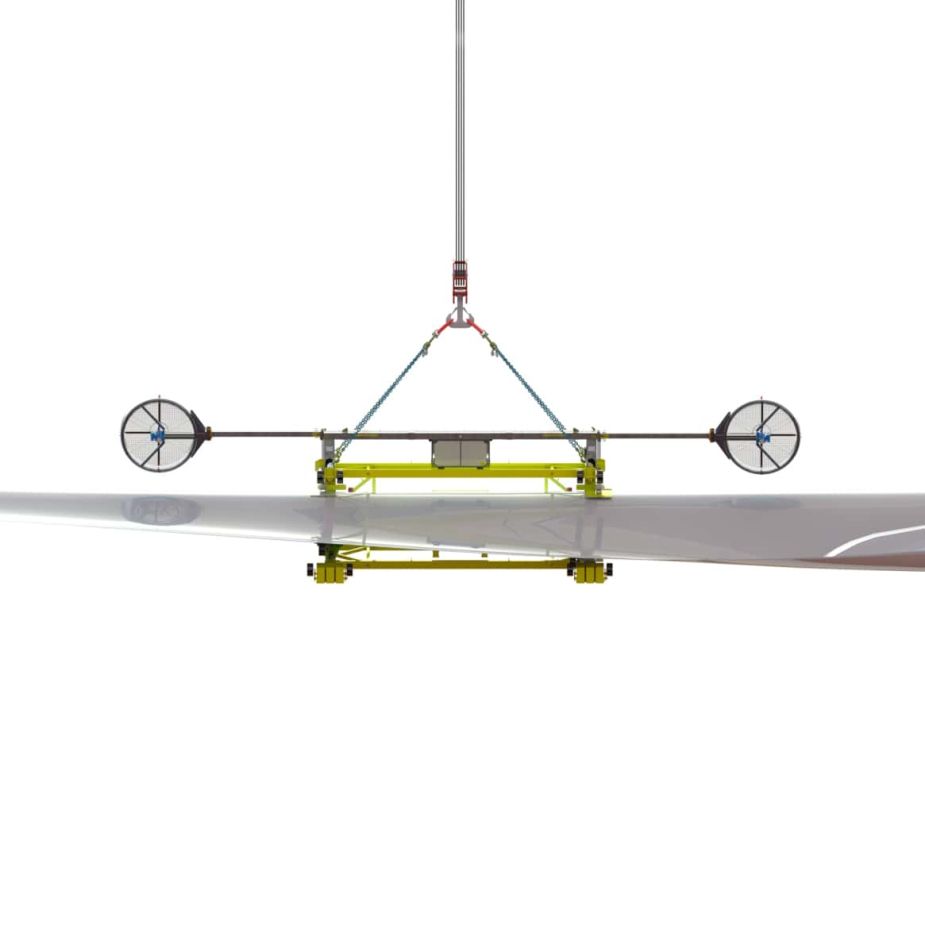

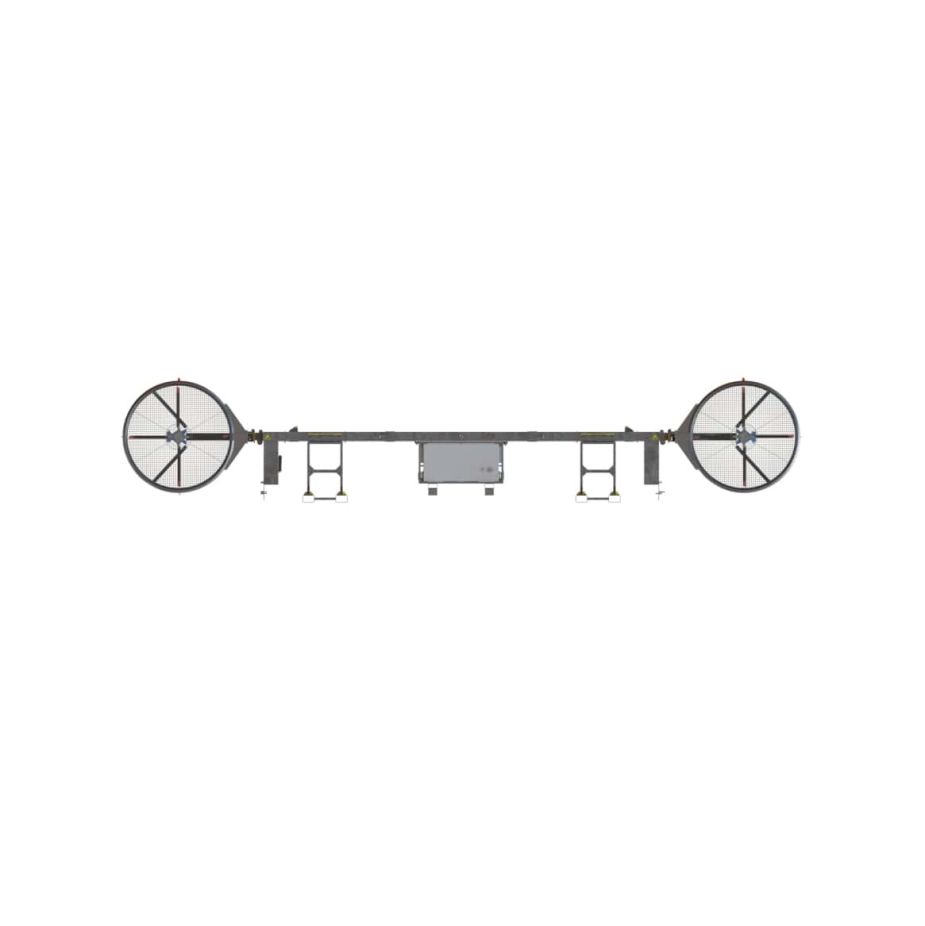

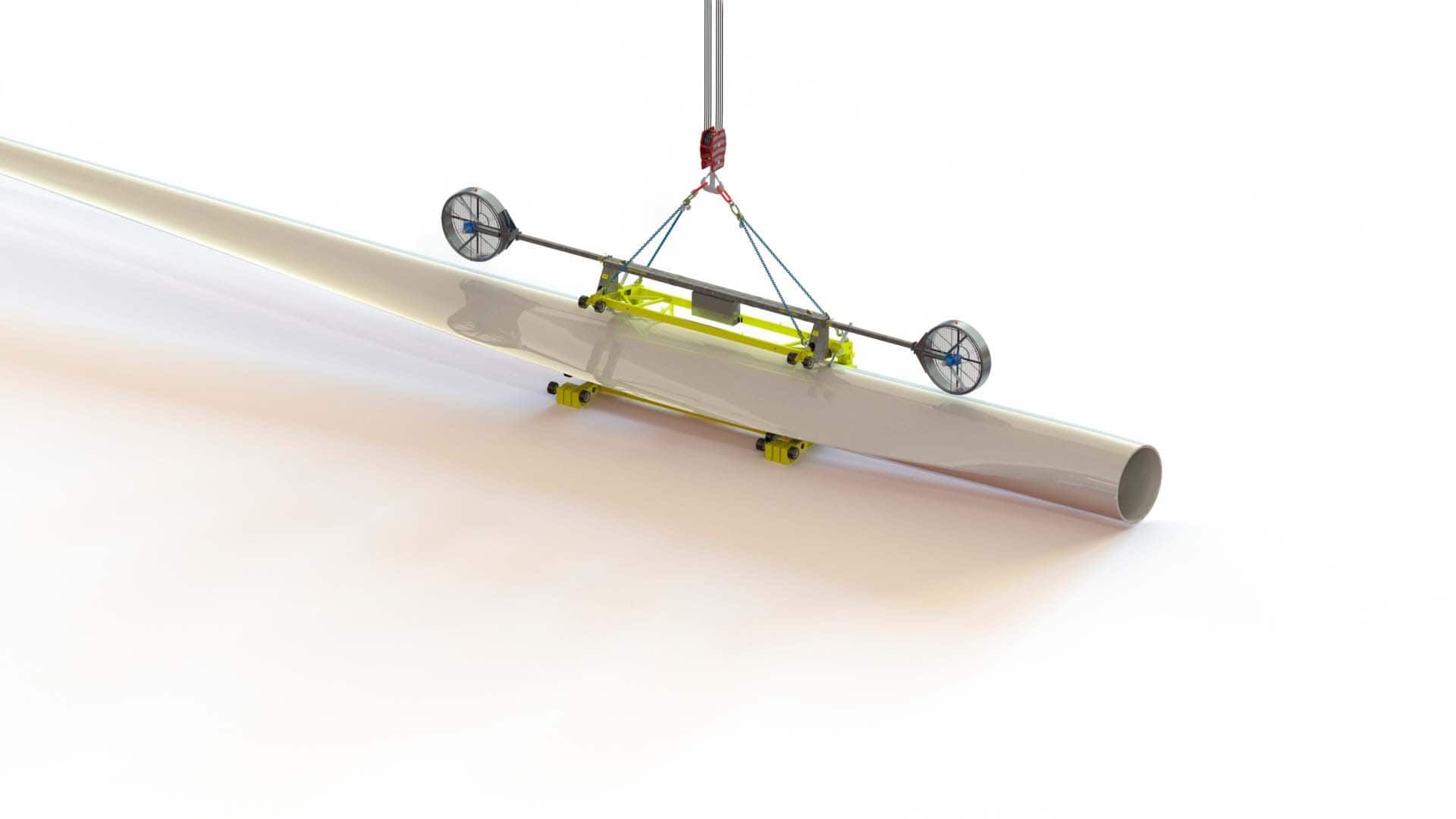

Hardware

Consists of- Two hubs with pitch propellers

- Two 15kw electric motors

- One control unit

- Two long range remote controls (min. 250 meters)

- Power supply option 1 – From the ground – 200 meters of 4G16, 32A reinforced electrical cable

- Power supply option 2 – 2 pcs generators connected in parallel for redundant power supply

-

Specifications

Consists of- Autonomous horizontal position stabilization via gyro setpoint

- Manual operation/control of horizontal position

- Operating temperature -20 to +50 degrees Celsius

- Ingress protection class IP 56

- CE marked according to Machinery Directive 2006/42/EC

- UV radiation resistant equipment

- System power supply redundancy

- Redundant propeller system

- Scada on system

- Net force: 2x750N (75 kg) – thrust is relative to distance from center of gravity

Total weight 1000 kg – depending on selected configuration

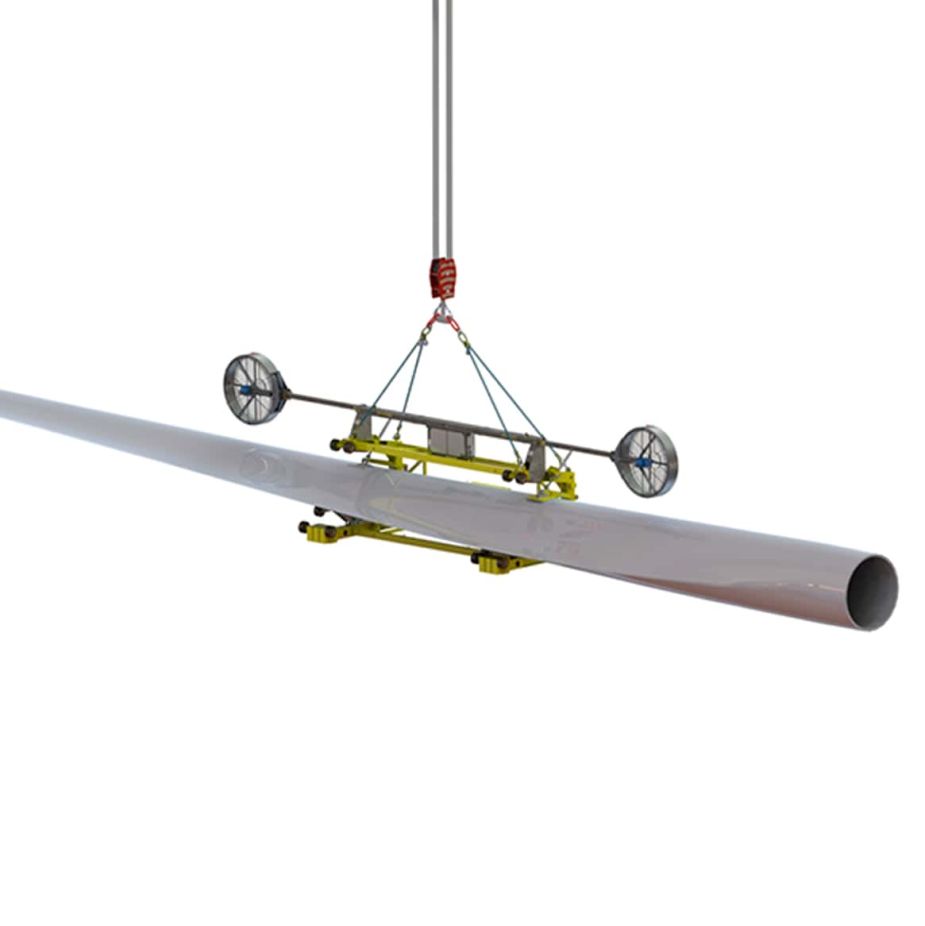

2 ways to configure the Autonomous Positioning System

APS-controlled sling load blade installation avoids taglines

Integrable system

The Autonomous Positioning System can be easily attached to or integrated with existing lifting equipment. Or even work as a stand-alone tool for sling load operations. Whether you need to lift components for wind turbine installation or assemble bridge sections, only your imagination limits the use of the system.

The most obvious use of the APS in the wind power industry is to control the lifting of wind turbine blades. These blades are designed to catch the wind while being lightweight. These are ideal conditions when the wind turbine is generating electricity, but challenging when the blades need to be installed or replaced. When lifting the blades, a strong support to keep them in precise position is mandatory for efficiency and safety. And simply to prevent the blade from accidentally turning into the tower or hub in a sudden gust of wind.

The APS is not only designed for blade lifting applications, but can also be used for other large components where precise positioning is essential.

Quick shift

The Autonomous Positioning System is designed with a quick-lock system for quick and secure integration with lifting equipment. This ensures no time is wasted on the jobsite. To enable this functionality, interface brackets must be added to your lifting equipment. Seasight Solutions has the experience and certifications to design and supply these brackets.

The alternative to the APS being fully integrated or designed as a Quick Shift solution to your lifting equipment is to use it as an independent tool under or above your payload/load.

With advanced software settings, even sling load configurations are possible.

Vestas EnVentus turbine – all major components installed with the Autonomous Positioning System.

Need for taglines is 100 % eliminated.

Need to use the APS? Here is how!

Planning and executing a wind turbine installation or component replacement is a complex supply chain activity.

Multiple contractors working together with expensive equipment and trained crews must ensure the construction schedule is met at all times. Clear agreements on the operational and commercial responsibility of each activity are of high importance. In the wind energy industry, the nature of construction planning and the legal responsibilities of the contractors on site are very diverse.

The APS is designed to work with any existing lifting yoke. Only unique interfaces need to be added to ensure safe and efficient operations.

Rent or buy?

Commercially, the Autonomous Positioning System aims to support the planning of construction activities by offering both purchase and rental solutions. This will accommodate the diversity and needs of different regions and wind farm construction subcontractors.

In any case, the APS will be delivered with product training and service contract packages, according to your preferred choice.

-

Mads Baden, CCO

+45 61 62 05 77 │ mbn@seasightsolutions.com -

Thomas Halkjær, CEO

+45 51 40 05 11│ thk@seasightsolutions.com -

Anders Karlsson, Head of Sales

+45 41 88 49 65│ aka@seasightsolutions.com